Automated winding of hub motor sections

28 travnja 2018

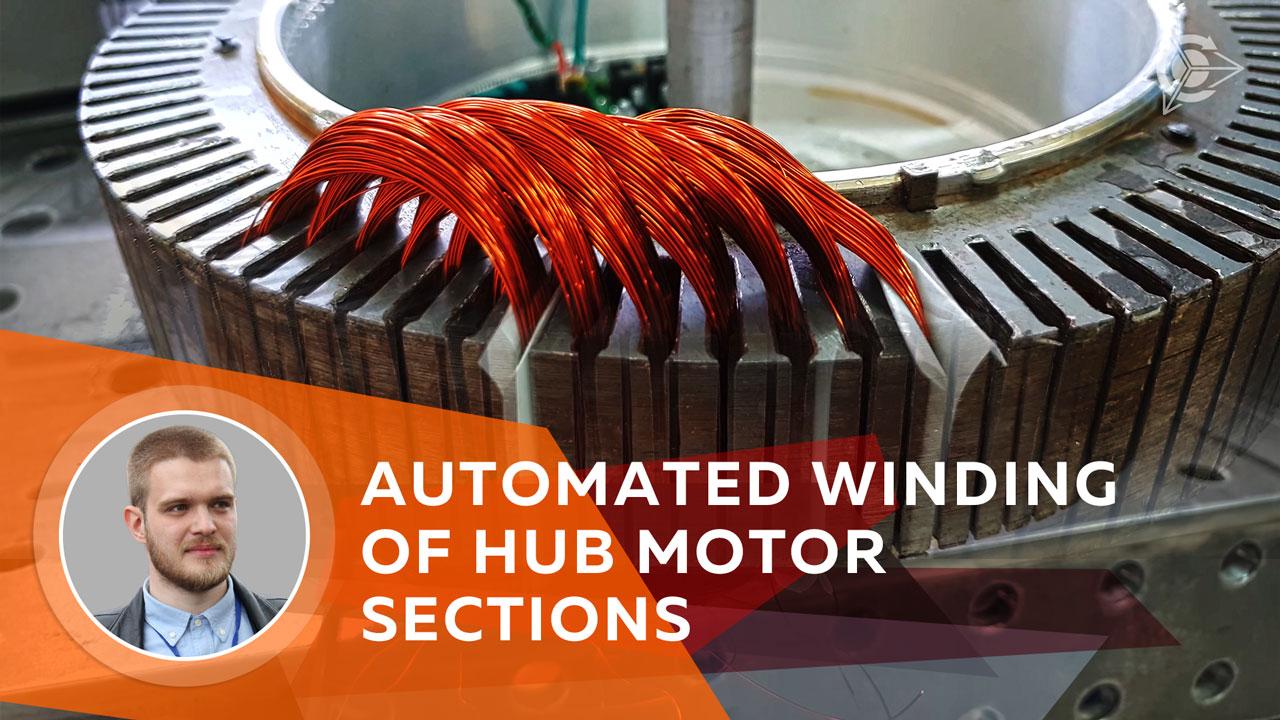

Evgeniy Duyunov showed the process of placing the hub motor sections on the winding machine. We used a draft version of tooling for winding 318 hub motor with 45 mm tyre width.

The machine provides fast section winding despite the fact that its speed is limited with 10% of maximum operating force.

Section mounting is done manually without any automated devices or machines, because the team aims at producing a prototype model rather than mass production.

Evgeniy concludes that automated winding increases the speed of prototype model production and contributes to the convenience of further mounting.

Using special equipment for winding the sections makes them look much more even which provides resistance equality of separate coil sections and improves hub motor marketable condition.

Duyunov's team has yet to refine the tooling and develop an expert technology of operating the machine.