"SovElMash": unpacking the equipment

Would you like to know more about the receipt inspection of the equipment delivered to "SovElMash"? You can see the unpacking process in this video.

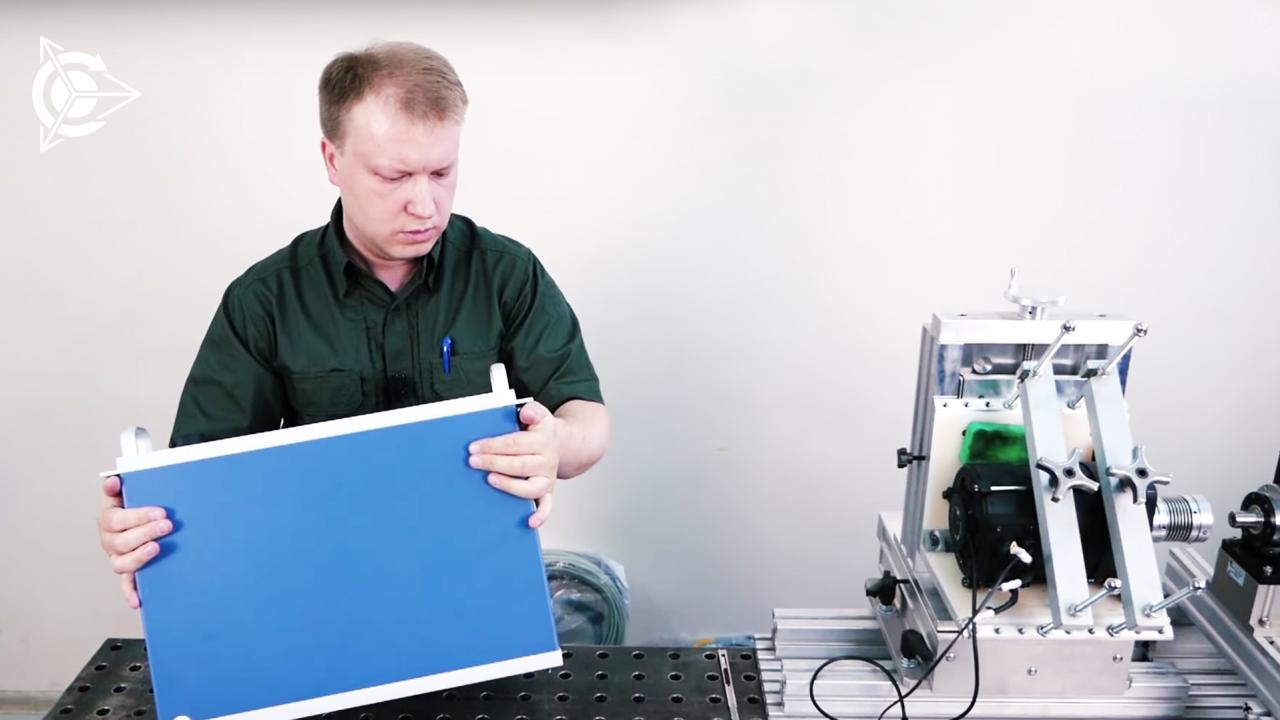

We have already shown you the first part of the video about the delivery of the loading bench, and today the head of the central plant laboratory of "SovElMash" Alexander Semenov is unpacking the box with the controller designed for controlling the brake machine. .

We are starting with what we have on the top: checking integrity of the power supply cables and presence of software discs, and also studying the calibration certificate.

We are taking out the controller itself and inspecting the body and plug connections to make sure there is no chipping, the contacts are not crimped, the buttons "sound" right. We are checking the serial numbers, model name. Complete inspection should not uncover any physical damage.

Then we are checking the completeness according to the documents. To do that, we are unpacking the remaining boxes and see the coupling for connecting the control object, that is our motor, to the load machine shift. This part is heavy, that's why it is thoroughly packed to protect it from transport damage. It's necessary to try it on to make sure the dimensions fit the machine.

After double-checking and making sure the constituent parts are unpacked, intact and comply with the stated performance characteristics, we can sign the Acceptance certificate.

At this point the receipt inspection is over. What stage do you think will be next?